Features

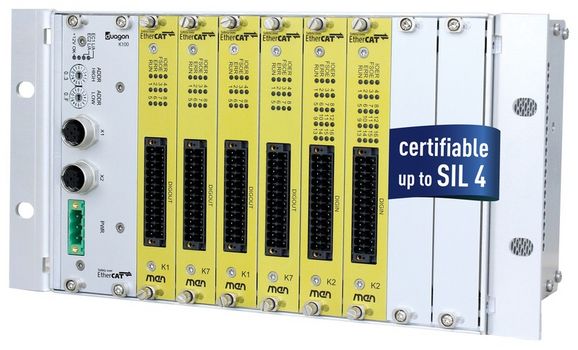

- For Applications up to SIL4 (EN5012x) or SIL3 (IEC61508)

- Safe I/O boards

- Certification packages available

- Distributed safe I/O and controller boxes connected via real-time Ethernet

- Support for QNX safe operating system

- Compact 40 HP housing for remote locations

- Full EN 50155 compliance

- Rack-mounted or wall-mounted